Show cart summary 0 Items

Please Add Some Items

- Home

- Blogs

- Did you know?

- What is the Span of the Filler Slab

- What is the ...

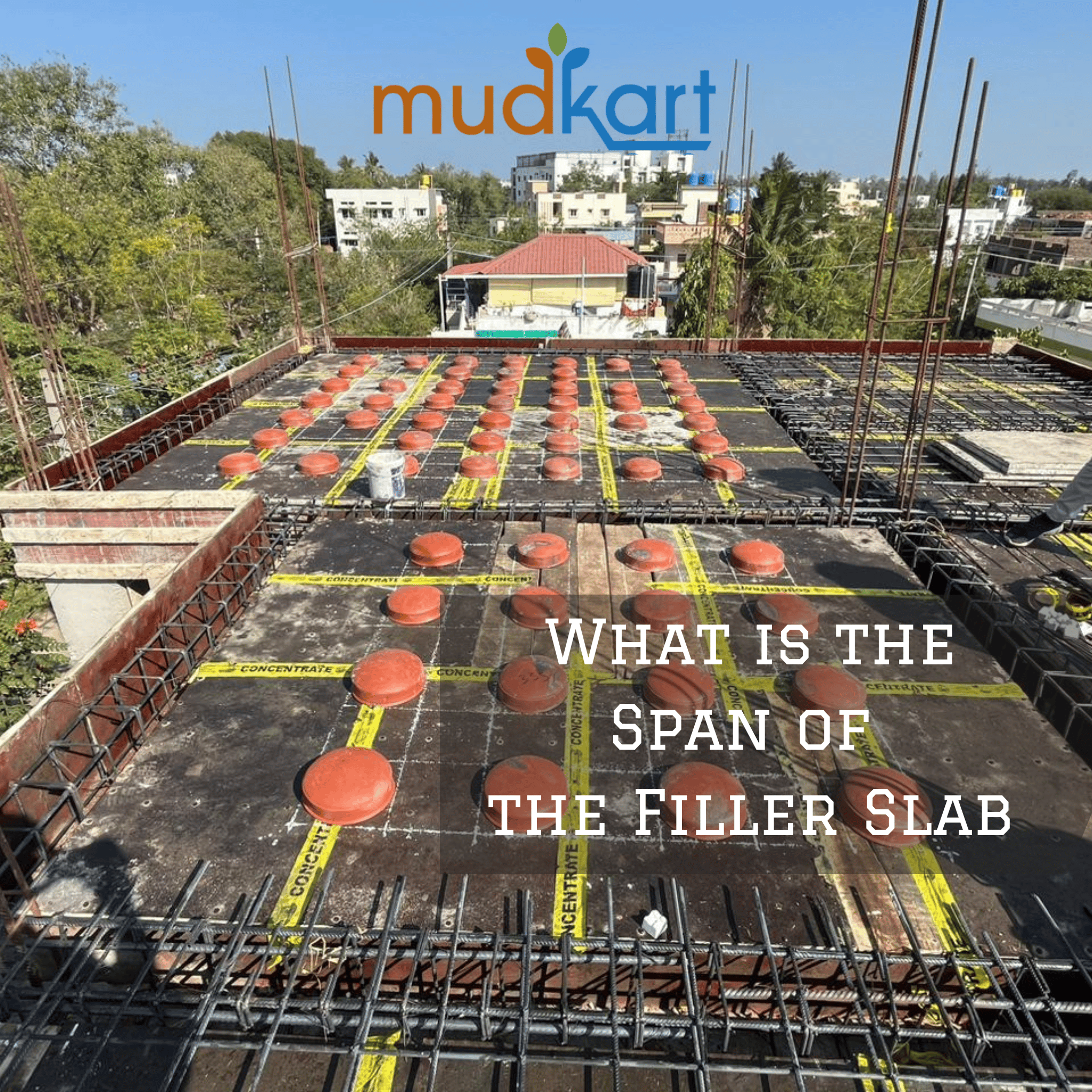

What is the Span of the Filler Slab

- By Dhinoj

- • Mar 18, 2024

Have you ever walked into a building and marveled at the beautiful ceiling designs, not realizing they could also be saving money and resources? This is where filler slabs come into play. It's a smart way to build more with less, focusing on sustainability and efficiency.

This method uses a unique approach to constructing ceilings and floors, incorporating materials like clay tiles, foam, or even recycled materials in between concrete slabs.

By doing this, not only is the building process greener, but it also reduces the weight and cost of construction. Choosing the right Filler Slab span is crucial because it ensures the building's safety, durability, and aesthetic appeal.

Keep reading to discover how this construction technique is revolutionizing the way we build, making our structures more sustainable, cost-effective, and visually appealing.

The Span of Filler Slabs An Overview

In building work, "span" refers to the distance between two supports in structures like bridges or slabs.

Several things influence how long the span can be. The material's strength is key – stronger materials can span greater distances. How weight is spread out also matters; even distribution can support a longer span.

Benefits of Optimal Span Calculation

Getting the span calculation right is super important. It makes sure the structure is both efficient and safe. If the span is too long for the material used, the slab might crack or even collapse.

On the other hand, a shorter-than-necessary span could mean using more materials and supports, which pushes up costs. By finding the optimal span, builders can save on materials and labour, making the project more budget-friendly.

There's also a green side to this. Using less concrete, which is often used in construction, is good for the planet. Concrete production releases a lot of CO2, a gas that warms the planet. So, less concrete means less CO2.

When builders opt for materials that are kinder to the Earth, like bamboo or recycled plastic, they further reduce the environmental impact.

How to Calculate the Right Span for Filler Slabs

Calculating the right span for your construction project involves understanding the distance over which the Filler Slabs can be safely supported without risking damage or failure.

Here's a simplified guide:

- Determine the total load expected on the slab. This includes the weight of the slab (consider the density and volume of the materials), permanent fixtures (like built-in cabinets), and an estimate of the live load (people, furniture, etc.).

- Consult the Building Codes in India, which provide guidelines for minimum requirements, including the span and load-bearing capacities. The Indian Standard (IS) 456:2000 is a good reference point.

- Use the formula for calculating the span Span = (Depth of beam x Load-bearing capacity of the material) / Total load. This formula can give you a rough idea, but it's essential to get professional advice for precise calculations.

- In terms of costs, factor in the price of materials (concrete, reinforcement bars, etc.), which can vary. You can expect to spend anywhere from ₹3,000 to ₹5,000 per square meter for the construction of a filler slab, depending on the materials and design.

*Prices are in Indian Rupees and are subject to change based on location and market fluctuations.

For accurate calculations and cost estimations, software like AutoCAD and STAAD Pro can be extremely helpful. These tools can help in designing and analyzing your structure, taking into account the specific materials and loads.

Common Mistakes to Avoid

- Ignoring the guidelines set by the Indian Standard (IS) codes can lead to structural failures. Always ensure your design meets or exceeds these standards.

- While it's helpful to understand the basics, consulting with a structural engineer is crucial for accurate calculations and safe designs.

- Using low-quality materials to cut costs can compromise the slab's strength and durability.

- Concrete needs time to reach its full strength. Not allowing adequate curing time can weaken the structure.

To avoid these pitfalls, always adhere to the Building Codes, accurately estimate loads, seek professional advice, use high-quality materials, and allow for proper curing. Keeping these points in mind will help ensure the safety and durability of your construction project.

Final Thoughts

Filler slabs represent an innovative construction approach, utilizing lightweight materials like clay pots, polystyrene, and even recycled items to fill voids in slabs. This method not only reduces the overall weight of the structure but also enhances insulation properties, making it both cost-effective and eco-friendly.

The design of these slabs includes materials that do not absorb much water and are compatible with the construction, ensuring durability and a reduced carbon footprint.

For more detailed insights and to explore sustainable building solutions further, consider researching Mudkart.

Tags: Filler Slab, Mudkart

0 Comment